Introduction

Single-use bioreactors streamline workflows and reduce contamination risks.

In today’s labs and manufacturing plants, being efficient is key to success. As we need more biologics, vaccines, and cell therapies around the world, it’s more important than ever to have production systems that are accurate, can grow, and are sustainable.

Instead of the old stainless-steel bioreactors, many are now using single-use bioreactor systems. These new systems are more flexible, reliable, and give better results. Companies like Thermo Fisher Scientific and Cytiva are leading the way, changing what’s possible in research and large-scale drug production.

Switching to these systems isn’t just about getting new equipment. It’s about changing the way scientists think about cell culture, making processes better, and how they manufacture things.

How Bi, Bioreactor Systems Have Changed

Modern bioreactor engineering enables cleaner, faster, and more scalable production.

Bioreactors are central to any bioprocess. They provide a controlled space where cells can grow and make useful biological products. For many years, stainless-steel tanks were the standard. But they needed a lot of cleaning, sterilization, and upkeep, which slowed things down.

The latest single-use bioreactors are made to fix these problems. They use disposable bags, advanced sensors, and computer software that makes every step easier—from starting the culture to harvesting the product.

Here are some key improvements in modern bioreactors:

- Disposable vessels: These pre-sterilized systems don’t need cleaning, which lowers the chance of contamination.

- Better automation: Automatic digital controls keep culture conditions just right.

- Scalability: These systems give the same results whether you’re working in a lab or making products on a large scale.

- Compact design: They take up less space and are set up in a way that increases space.

- Real-time data: Continuous monitoring helps you understand the process better and get consistent results.

These features help biotech companies work faster, stay consistent, and change as production needs.

The Advantage of Single-Use Technology

The biggest change in bioprocessing today is using single-use technology (SUT). By using disposable parts for each production run, SUT means less downtime and more flexibility.

Faster Turnaround Times

Old systems can take days to clean and prepare. Single-use bioreactors are ready to go, so you can start right away and change production quickly.

Less Risk of Contamination

Each batch runs in a sterile, closed system, which lowers the risk of contamination and keeps the product pure.

Cost and Resource Savings

Since you don’t have to clean things, you save water and energy. This means lower costs and less environmental impact.

More Flexibility

Single-use systems can handle different products in the same facility. This is great for contract manufacturers and R&D labs that work with different molecules.

All these things help labs be more operationally flexible.

Thermo Fisher’s HyPerForma: Made for Performance and Accuracy

The Thermo Fisher HyPerForma Single-Use Bioreactor is one of the best systems out there. It’s made to give consistent results at any scale, from research to commercial production.

Key Features:

- Better mixing for better oxygen and nutrient distribution.

- A design that keeps process parameters the same at different volumes.

- Built-in automation that works with DeltaV and other control systems.

- Quick setup with disposable parts and simple.

- Strong enough to handle demanding biologics manufacturing.

The HyPerForma series can be used for different cell culture jobs, like making monoclonal antibodies, vaccines, and viral vectors. It’s accurate and scalable, making it a favorite for facilities switching to fully single-use production.

Cytiva XDR: Efficient and Well-Engineered

The Cytiva XDR bioreactor platform combines traditional engineering with single-use technology. It’s known for great mixing and fluid flow, which ensures consistent results.

Key Advantages:

- Very mixing for high-density cell cultures.

- Good for batch, fed-batch, and perfusion processes.

- Easy-to-use control interface with simple programming and monitoring.

- Scales up well from 50 L to 2000 L without losing performance.

Many global biotech companies trust Cytiva’s XDR systems because they are reproducible and easy to use. They help speed up process development and make technology transfer easier across facilities.

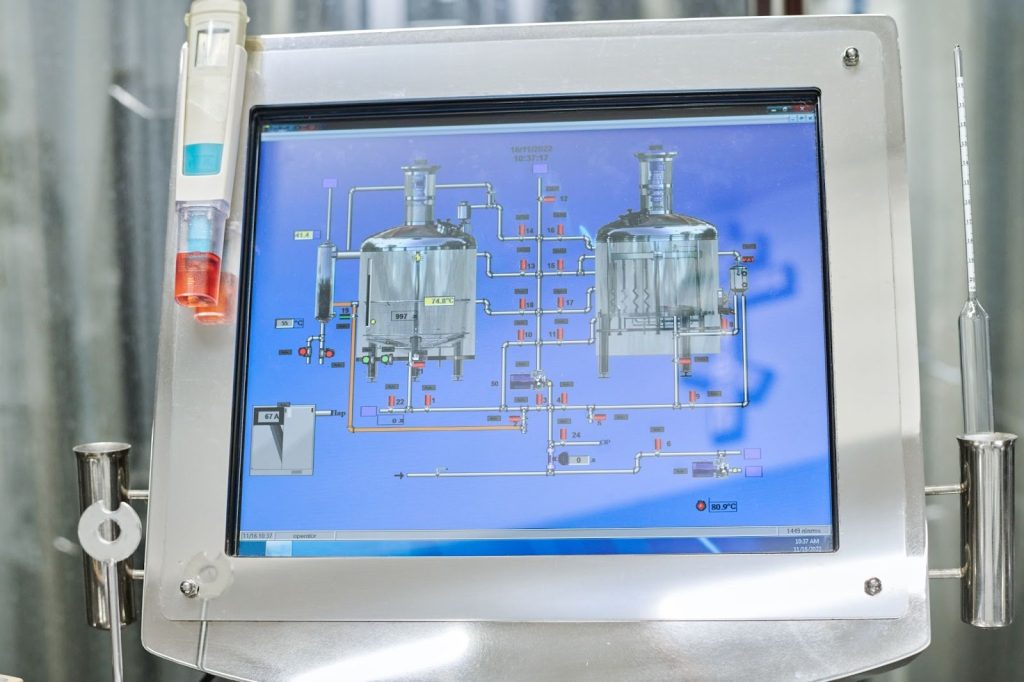

Automation: The Digital Core of Modern Bioprocessing

Advanced automation gives researchers precise control and real-time insights.

Automation is a game-changer in today’s bioreactor systems. Sensors, controllers, and software let scientists track and adjust things in real time.

Benefits:

- Better accuracy and consistency. Automated systems remove the inconsistencies of manual control.

- Data-driven improvements. Continuous monitoring gives you information to fine-tune conditions and increase yield.

- Less labor needed. Automation lets skilled staff focus on coming up with new ideas instead of routine tasks.

- Remote monitoring. Scientists can check process data from anywhere, which improves flexibility and response time.

Automation also helps with regulatory compliance by keeping a digital record of every step, which is important for GMP documentation.

Sustainability and Environmental Impact

As being sustainable becomes more important, modern bioreactor systems help lower environmental impact.

Single-use systems use less water and chemicals because they don’t need cleaning or sterilization procedures. They also use less energy and make waste management simpler.

Even though single-use systems create disposable materials, many manufacturers now have recycling and energy recovery programs. When you look at the whole product lifecycle, single-use systems often have a smaller carbon footprint than stainless-steel systems.

This makes them efficient and responsible choices for biotech and pharmaceutical companies.

Ensuring Consistent Product Quality

The most important thing in any bioprocess is consistency. Even small differences in mixing, aeration, or pH can affect cell growth and product yield.

Modern bioreactors have accurate sensors and feedback systems that constantly adjust critical parameters. This makes sure culture conditions are the same throughout the vessel and product quality is predictable across every batch.

This accuracy is important for making biologics, where product effectiveness and safety depend on consistent process performance.

Real-World Impact: Examples

Case 1 – HyPerForma DynaDrive Success

A biopharmaceutical company scaling up from a 250 L pilot to a 5000 L production run used the HyPerForma DynaDrive bioreactor. The process kept the same growth rates and, which showed it was scalable and reduced tech-transfer time.

Case 2 – Cytiva XDR in Cell Therapy Production

A leading cell therapy manufacturer used Cytiva XDR systems for their GMP suite. The consistent mixing and quick turnaround helped cut production cycle times by 25%, which improved facility.

Case 3 – Hybrid Facilities

Some organizations now use both HyPerForma and XDR platforms in different stages of development. This gives flexibility in process design while keeping high reproducibility.

Challenges and Best Practices

Even though there are many good things, there are challenges to adopting new bioreactor technologies:

- Operators need training to assemble and dispose of single-use parts.

- Supply chain management needs to make sure consumables and spare parts are available.

- Process needs to be verified when switching from stainless-steel to single-use systems to make sure performance is the same.

- Waste management needs to follow local environmental rules.

By following best practices in system setup, training, and supplier management, facilities can overcome these challenges and use the of modern bioreactors.

The Future of Bioreactor Technology

Bioreactor technology is still changing quickly. The next will use artificial intelligence, predictive analytics, and continuous bioprocessing to make even more efficiency.

Trends:

- AI-driven control systems that automatically adjust feed rates and environmental parameters.

- Digital copies for real-time simulation and process.

- Continuous bioprocessing, which allows nonstop production with very little downtime.

- Eco-friendly materials made for recycling or.

- Compact modular systems for fast setup in flexible manufacturing.

These will make future labs smarter, greener, and more efficient.

Conclusion

Modern bioreactor systems have changed how labs and pharmaceutical manufacturers work. With single-use technology, automation, and digital control, platforms like Thermo Fisher’s HyPerForma and Cytiva’s XDR have made new standards for efficiency, reliability, and sustainability.

By making setup easier, lowering contamination risk, and allowing accurate process control, these systems let scientists focus on finding new things instead of maintenance and downtime.

In the future, as we continue to make progress in, bioreactors will still be key to scalable, high-quality, and environmentally conscious manufacturing. They’re not just tools — they’re what makes bioprocessing efficient.